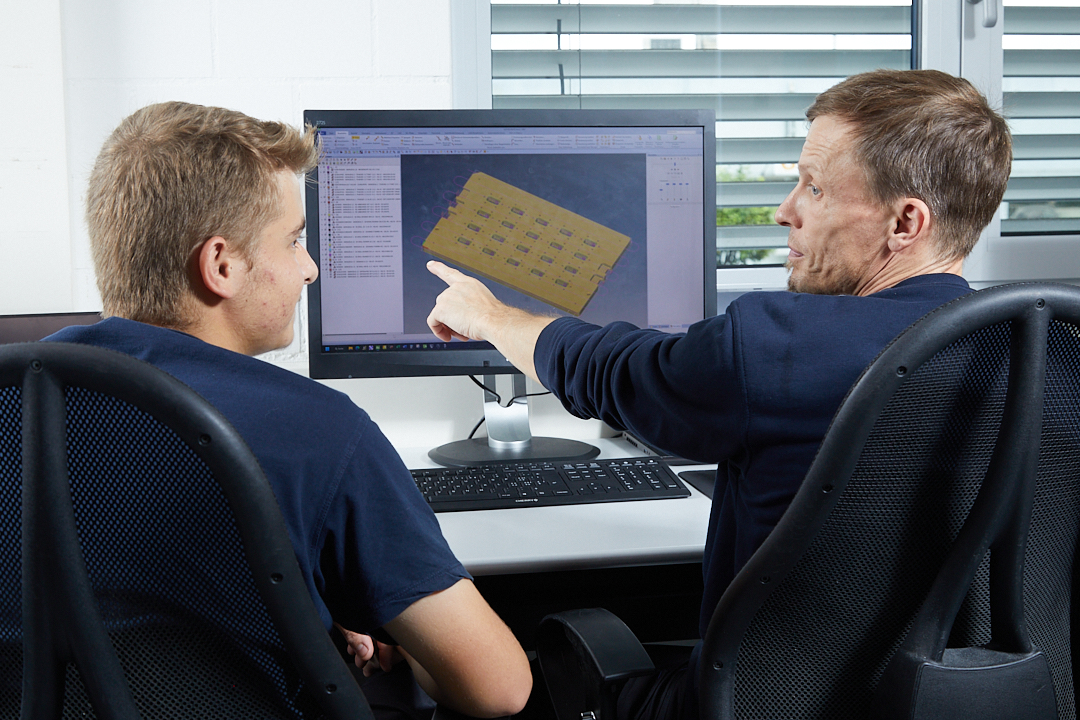

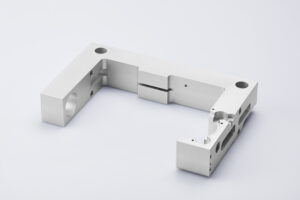

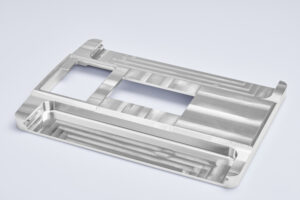

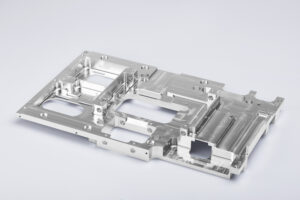

CNC milled parts

As a supplier of CNC milled parts and assemblies as well as customised machines and systems, Hagmann has more than 40 years of experience.

Thanks to our lean processes, we are able to react quickly to customer

to react quickly to customer requirements and offer high-quality products with short delivery times.

Hagmann attaches great importance to high quality and carries out in-process and final inspections to ensure that customers receive the desired quality.

Deliveries are made according to the customer’s requirements, be it call-off, Kanban or just-in-time.

We are experienced in the processing of framework agreements,

call-off orders or individual orders with precise delivery dates.